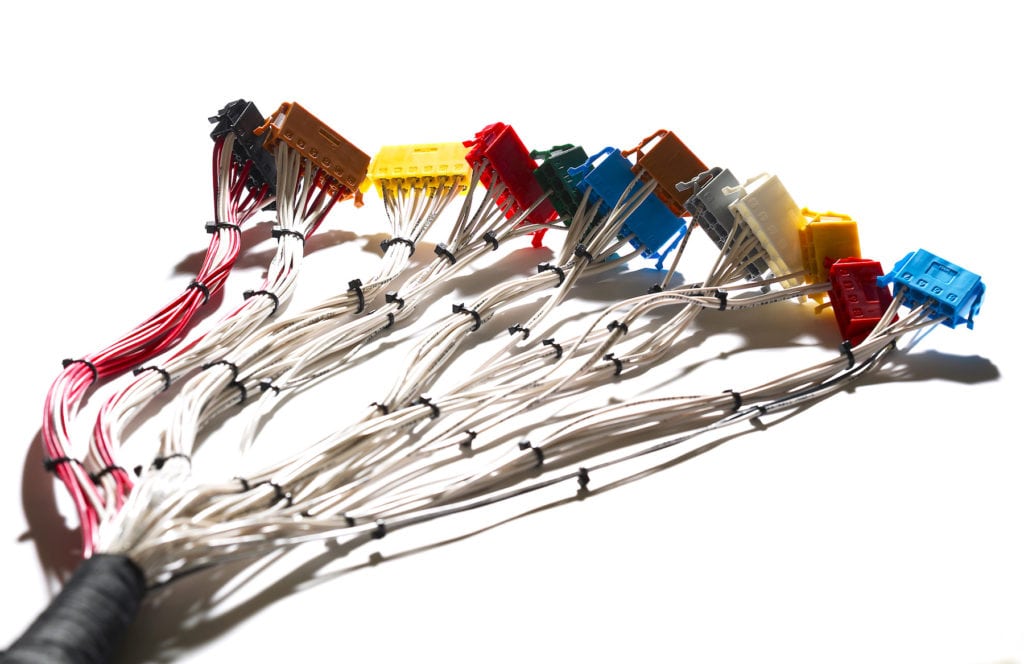

In the modern world of complex electronic systems, wire harnesses serve as the circulatory system, efficiently carrying electrical signals and power to various components. A wire harness is a bundle of wires and cables, organized and secured together with connectors, terminals, and protective sheathing. The wire harness manufacturer plays a crucial role in designing, assembling, and supplying these intricate and customized wiring solutions for a wide range of industries, including automotive, aerospace, telecommunications, and industrial machinery.

Design and Engineering Expertise

They are equipped with skilled design and engineering teams that work closely with clients to understand their specific needs and requirements. The process starts with comprehensive consultations, during which the manufacturer gains insights into the client’s application, performance expectations, space constraints, and environmental considerations.

Precision Assembly and Manufacturing

Once the wire harness design is finalized, the manufacturing process commences with precision and attention to detail. Automated cutting and stripping machines precisely trim and prepare the wires to the required length, and specialized crimping machines apply connectors with consistent accuracy.

Quality Assurance and Testing

Quality assurance is a top priority for wire harness manufacturer. Throughout the manufacturing process, rigorous inspections are conducted to ensure that each wire harness adheres to the specified design and meets industry standards. Automated testing equipment is employed to verify continuity, insulation integrity, and connector functionality, guaranteeing that the harness performs flawlessly under real-world conditions.

Some manufacturers may carry out additional specialized testing, such as thermal cycling and vibration tests, to assess the durability and reliability of the harness in demanding environments. The commitment to quality ensures that the finished wire harnesses meet the highest standards of performance and reliability.

Customization and Versatility

One of the key advantages of working with a manufacturer is the ability to create highly customized solutions tailored to specific applications. Wire harnesses can vary widely in complexity, from simple point-to-point connections to intricate multi-branch configurations.

Manufacturers can accommodate unique requirements such as connector compatibility with various electronic devices, specific wire lengths for efficient cable management, and connector orientation for ease of installation. This level of customization and versatility allows wire harnesses to seamlessly integrate into diverse systems, promoting streamlined operations and enhanced performance.

Applications in Various Industries

Wire harnesses find applications in numerous industries, each with its unique demands and challenges. In the automotive sector, wire harnesses are critical components in vehicles, connecting electrical systems, sensors, and electronic control units. Aerospace and defense industries rely on wire harnesses to provide robust electrical connections for avionics, communication systems, and flight controls.

Telecommunications industries utilize wire harnesses for data transmission and networking equipment, while industrial machinery relies on these harnesses to ensure efficient power distribution and control. Medical devices, consumer electronics, and renewable energy systems are among other sectors that benefit from the expertise of manufacturers.

They are vital partners in providing essential electrical connectivity solutions for a wide range of industries. Their expertise in design, engineering, and manufacturing ensures that wire harnesses meet stringent performance requirements while seamlessly integrating into complex systems. The ability to create customized solutions, coupled with a strong commitment to quality, makes them essential contributors to the advancement of modern technology and the seamless integration of electrical components in various applications.